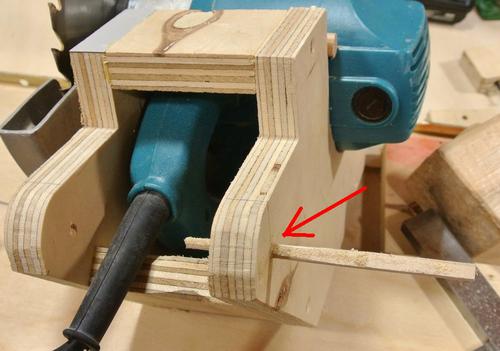

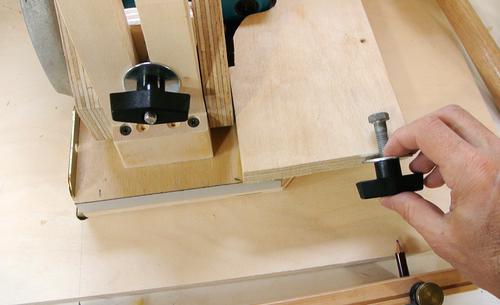

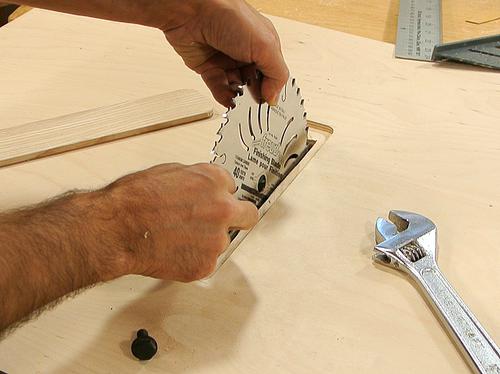

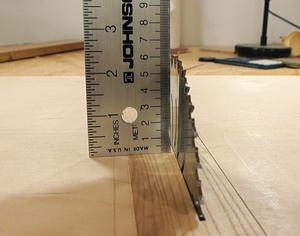

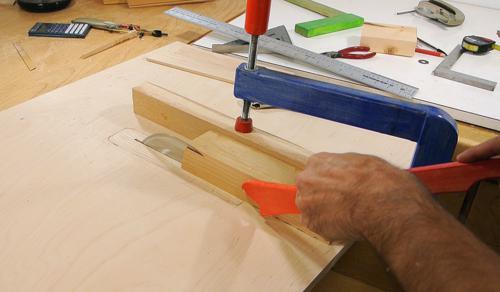

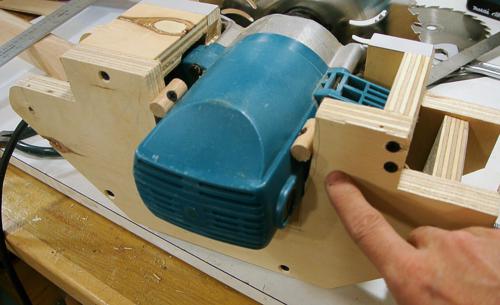

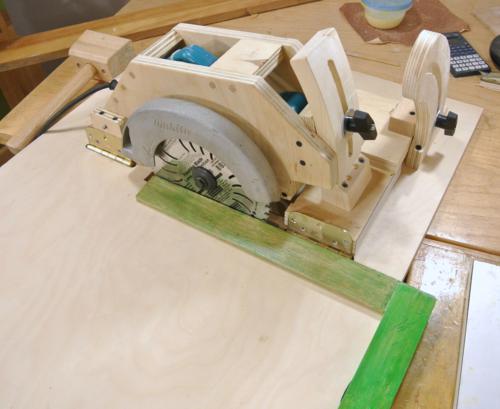

Homemade table saw: Angle lock and table saw inserts(Back to part 1) From my previous tests, I found that the blade moved slightly side to side as I changed the depth setting. Checking it over, I found I had one of the holes that the saw unit pivots on about 2 mm off. I had previously compensated for that by shimming the pivot mounts, but the slightly crooked tilt axis resulted in a slight side-to-side movement during plunging. So time to fix that. From my previous tests, I found that the blade moved slightly side to side as I changed the depth setting. Checking it over, I found I had one of the holes that the saw unit pivots on about 2 mm off. I had previously compensated for that by shimming the pivot mounts, but the slightly crooked tilt axis resulted in a slight side-to-side movement during plunging. So time to fix that. I glued a peg into that hole and then re-drilled it in the correct spot. I glued a peg into that hole and then re-drilled it in the correct spot. Next challenge: making a tilt angle locking mechanism. Next challenge: making a tilt angle locking mechanism.I decided to make some sort of knob attached to the tilting frame that pinches against a curved slot.  I laid out the shape of the curved slot on a scrap of plywood using a beam compass. I laid out the shape of the curved slot on a scrap of plywood using a beam compass. I mostly cut it out on the bandsaw, but cut the slot by drilling a hole on either end and cutting between with a jigsaw. I mostly cut it out on the bandsaw, but cut the slot by drilling a hole on either end and cutting between with a jigsaw. A block of wood holds the bolt for the knob. The bolt fits tightly in the wood (I drilled the hole 1/64" (0.4 mm) undersized, then hammered the bolt into the hole). A block of wood holds the bolt for the knob. The bolt fits tightly in the wood (I drilled the hole 1/64" (0.4 mm) undersized, then hammered the bolt into the hole). Mounting the locking piece on the underside of the table. Mounting the locking piece on the underside of the table.It turned out, my slot covered a bit more than 45 degrees, and the end of the piece gets a bit in the way of the depth adjustment mechanism, so I shortened it a little.   With the saw all the way down, it barely withdraws the blade from the slot far enough to tilt. With the saw all the way down, it barely withdraws the blade from the slot far enough to tilt. Up to this point, I had been turning the saw on and off by plugging it in and unplugging it. I finally made a "switch" for it by installing a light switch in a cheap extension cord. Up to this point, I had been turning the saw on and off by plugging it in and unplugging it. I finally made a "switch" for it by installing a light switch in a cheap extension cord.But then I left that switch on the floor, where I could turn it on accidentally with my feet, so I still ended up unplugging the saw when working on it.  Making a 45 degree plunge cut from below. Very dusty! Making a 45 degree plunge cut from below. Very dusty!  With where the blade comes through the table at 45 degrees and 90 degrees, I would need a VERY wide slot to accommodate all the angles. With where the blade comes through the table at 45 degrees and 90 degrees, I would need a VERY wide slot to accommodate all the angles.A solution would be to build trunnions, like on my bandsaw, instead of using hinges for the angle adjustment. But I wanted to keep this saw as something relatively easy to build. Besides, this will never be a really good table saw.  So my solution was to route a cavity for a table saw insert into the table. So my solution was to route a cavity for a table saw insert into the table.This time, I used one of my fixed routers with a dust collection hose attached. Much much nicer to work with than a plunge router, hardly any dust goes flying.  I then cut an opening inside the cavity with my jigsaw. I then cut an opening inside the cavity with my jigsaw. I made several inserts to fit in this slot. These are just pieces of ash. I made several inserts to fit in this slot. These are just pieces of ash. I made the slot large enough that even a 8 1/4" blade can be inserted through the top. I made the slot large enough that even a 8 1/4" blade can be inserted through the top.The circular saw was designed for a 7 1/4" blade, but with the retracting blade guard removed, a 8 1/4" blade will just barely fit inside the outer guard.  Cutting the slot in the insert with a plunge cut. Cutting the slot in the insert with a plunge cut. With the 8 1/4" (210 mm) blade, I can get a depth of cut of 60 mm, or 2 3/8". That's about the same depth that the circular saw could do originally. So the larger blade just makes up for depth that I lost because of the thick plywood table. With the 8 1/4" (210 mm) blade, I can get a depth of cut of 60 mm, or 2 3/8". That's about the same depth that the circular saw could do originally. So the larger blade just makes up for depth that I lost because of the thick plywood table. I used one of my long reach C-clamps to attach a temporary fence and made another test rip cut. I used one of my long reach C-clamps to attach a temporary fence and made another test rip cut. Surprisingly, the cut surface had a bit of a shine to it, even though I was cutting soft wood. But deeper cuts are usually cleaner. I was also using a brand new blade. Surprisingly, the cut surface had a bit of a shine to it, even though I was cutting soft wood. But deeper cuts are usually cleaner. I was also using a brand new blade. But I had to mount the fence slightly off from perpendicular to the edge of the table. So more checking of the alignment. The saw turned out to be at a slight angle in the mount. I cut the opening for the back of the motor a bit wider and, using two dowels wedged in, locked it at the new position. But I had to mount the fence slightly off from perpendicular to the edge of the table. So more checking of the alignment. The saw turned out to be at a slight angle in the mount. I cut the opening for the back of the motor a bit wider and, using two dowels wedged in, locked it at the new position. Re-checking it, it looks pretty square. Re-checking it, it looks pretty square. I also made a dust deflector. Too much of the sawdust dust coming off the saw was thrown towards me. Not fun. This deflector should throw it down. I also made a dust deflector. Too much of the sawdust dust coming off the saw was thrown towards me. Not fun. This deflector should throw it down. Dust flying, while making a cut. There's dust everywhere, though it's no longer thrown at me quite as much. Dust flying, while making a cut. There's dust everywhere, though it's no longer thrown at me quite as much. Now making a plunge cut in my first 45 degree insert. Now making a plunge cut in my first 45 degree insert.  Cutting out a test shape with 45-degree angles. Cutting out a test shape with 45-degree angles.This is the sort of thing that would be very difficult to make without a tilting arbour table saw.  And most of the dust ended up underneath the saw, so the dust deflector helped, though not as much as I had hoped. And most of the dust ended up underneath the saw, so the dust deflector helped, though not as much as I had hoped.Next: Table saw rip fence See also: Back to my Woodworking website. |

Monday, 8 December 2014

Homemade table saw: Angle lock and table saw inserts

Subscribe to:

Post Comments (Atom)

Homemade tablesaw

Homemade tablesaw Fixing my old table saw

Fixing my old table saw Making table saw inserts

Making table saw inserts Homemade

Homemade

No comments:

Post a Comment