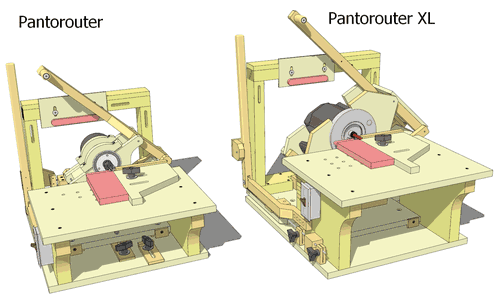

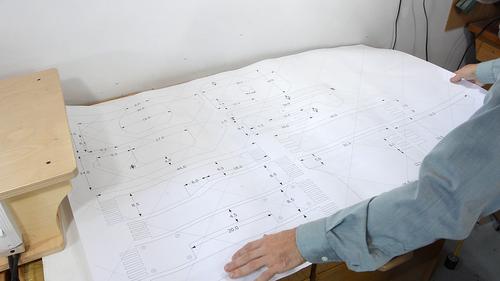

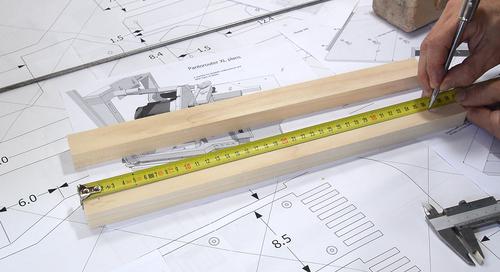

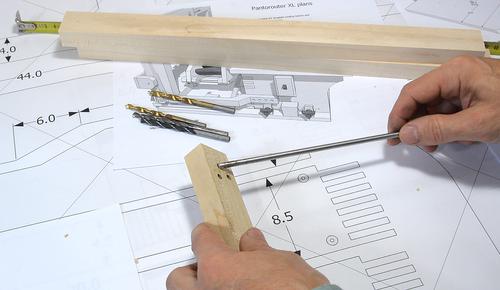

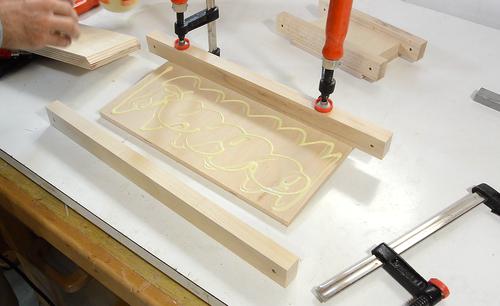

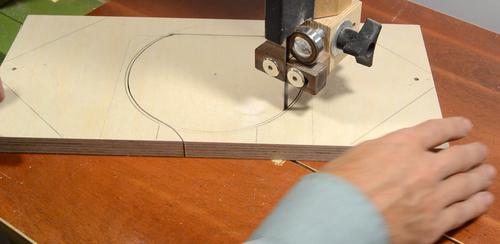

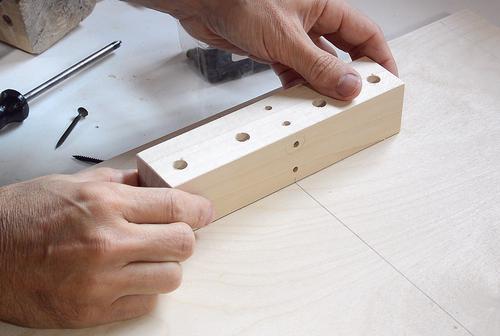

Building the pantorouter XL pantographWhy the pantorouter XL?  A frequently asked question from readers wanting to build the pantorouter is where to get that style of router. This style of router, with a motor that pulls out of interchangeable bases (likethis one) is hard to find outside of North America. This is probably because other countries require that the router turn off when you let go of the handle, and that necessitates putting the switch on the handles, and that's difficult to do with the motor detaching from the base and handles. A frequently asked question from readers wanting to build the pantorouter is where to get that style of router. This style of router, with a motor that pulls out of interchangeable bases (likethis one) is hard to find outside of North America. This is probably because other countries require that the router turn off when you let go of the handle, and that necessitates putting the switch on the handles, and that's difficult to do with the motor detaching from the base and handles. Outside of Canada and USA, except for a few brands and models, routers are plunge routers, with the body and handles often consisting of one piece. This type of router is too bulky to fit into the pantograph mechanism of my original pantorouter design. Outside of Canada and USA, except for a few brands and models, routers are plunge routers, with the body and handles often consisting of one piece. This type of router is too bulky to fit into the pantograph mechanism of my original pantorouter design. So I designed the "Pantorouter XL", which has a larger pantograph mechanism for mounting a plunge router, complete with handles, in the pantograph. So I designed the "Pantorouter XL", which has a larger pantograph mechanism for mounting a plunge router, complete with handles, in the pantograph.Building the pantograph I printed out my plans, including a sheet (pasted together from many pages) with a lot of the parts in full size using my BigPrint program. I printed out my plans, including a sheet (pasted together from many pages) with a lot of the parts in full size using my BigPrint program. The long parts of the pantograph link are made from hard maple. Here, I'm cutting the parts out of a piece of firewood. The long parts of the pantograph link are made from hard maple. Here, I'm cutting the parts out of a piece of firewood. Marking where the holes need to end up. These measurements are very critical. Marking where the holes need to end up. These measurements are very critical. The links will pivot on some 3/16" (5 mm) steel rod. Getting holes of just the right fit is important. I drilled some test holes with different 3/16" brad point bits, but these all drilled slightly oversized, resulting in a fit that had a tiny amount of play in it. The links will pivot on some 3/16" (5 mm) steel rod. Getting holes of just the right fit is important. I drilled some test holes with different 3/16" brad point bits, but these all drilled slightly oversized, resulting in a fit that had a tiny amount of play in it.I ended up drilling the holes at 11/64 (1/64" or 0.4 mm smaller than I needed), and then drilling the holes to final size using a regular (not brad-point) drill bit. This resulted in a very tight fit with the rod, which is what I was aiming for.  Starting to assemble the links. Starting to assemble the links.Freshly applied glue is very slippery, so to keep parts aligned, I clamp on one of the long pieces to the plywood without any glue, then apply glue to the thinner bottom layer...  ... and glue on the next (18 mm) thick layer, using the clamped-only piece to help align it. ... and glue on the next (18 mm) thick layer, using the clamped-only piece to help align it.Next I glue on the other long piece of hardwood.  I gave it a few minutes, the glue on the first joint set sufficiently to no longer slide around. Then I removed the first (clamped but not glued) piece of hardwood, and clamped on the second piece. I gave it a few minutes, the glue on the first joint set sufficiently to no longer slide around. Then I removed the first (clamped but not glued) piece of hardwood, and clamped on the second piece.I wanted to remove that first piece of hardwood, otherwise, the glue that squeezed out from gluing on the plywood would have made it very difficult to remove later.  With the glue dry enough, I can now glue on the other rail to the pantograph links (the rail that I initially only clamped but not glued on). With the glue dry enough, I can now glue on the other rail to the pantograph links (the rail that I initially only clamped but not glued on).It's very important that the pieces align laterally. Here, I'm checking that alignment with a square.  Rather than follow the dimensions in the CAD drawing, it's best to use the geometry of your router base instead. This will make it easier to fit the router later. Rather than follow the dimensions in the CAD drawing, it's best to use the geometry of your router base instead. This will make it easier to fit the router later. Cutting out the pieces on the bandsaw. Cutting out the pieces on the bandsaw. Cutting up some pieces of 3/16" (5 mm) steel rod for the pivot pins. Cutting up some pieces of 3/16" (5 mm) steel rod for the pivot pins. With the pins fitting in the links very tightly, I made a sort of reamer out of a piece of the steel rod, by cutting a lengthwise slot near the end with a hacksaw. With the pins fitting in the links very tightly, I made a sort of reamer out of a piece of the steel rod, by cutting a lengthwise slot near the end with a hacksaw. I then used that steel rod in a drill to expand the holes for a very snug and only slightly tight fit. I then used that steel rod in a drill to expand the holes for a very snug and only slightly tight fit.The holes are not necessarily perfectly aligned with each other, so I take the reamer, push it through the hole on one side, and then into the hole on the other side. I do this coming in from both sides to get both holes into alignment. A number of people have "improved" on my design by drilling larger holes and using bronze bushings in the holes. But that means you can't use this trick to get the holes fully aligned. The bronze bushings do last longer. A steel rod in a wooden hole might wear out after cutting as few as ten thousand joints. But if you are at all concerned about wear, put oil in the holes and polish the rods, and it should last much longer.  First test assembly of the pantograph mechanism. First test assembly of the pantograph mechanism. Fitting that blue Ryobi plunge router is a challenge. The handles are not detachable and very bulky. I first thought it wouldn't fit (with the pantograph tilted by just over 45 degrees from square). Fitting that blue Ryobi plunge router is a challenge. The handles are not detachable and very bulky. I first thought it wouldn't fit (with the pantograph tilted by just over 45 degrees from square). But then I realized, in my design, the pantograph only needs to tilt by 30 degrees off square. Here I added some blocks of wood below the router mount to limit the tilt to just over 30 degrees off right angle. But then I realized, in my design, the pantograph only needs to tilt by 30 degrees off square. Here I added some blocks of wood below the router mount to limit the tilt to just over 30 degrees off right angle. At that tilt angle, the handles do not interfere with the links - though they do interfere with the back plate. At that tilt angle, the handles do not interfere with the links - though they do interfere with the back plate.  The pantograph needs to be mounted on a base, and the base has two corners cut away to fit in the machine, as designed. I mostly cut these on the table saw, then finished the corner cuts on the bandsaw. The pantograph needs to be mounted on a base, and the base has two corners cut away to fit in the machine, as designed. I mostly cut these on the table saw, then finished the corner cuts on the bandsaw. Drilling the holes in the mounting blocks for the pantograph. Drilling the holes in the mounting blocks for the pantograph.These need to be very square. To compensate for any non-square-ness that my drill press may have, I drill the hole about 5 mm in then rotate the block 180 degrees (around the axis of the drill bit) and drill another 5 mm, repeating until I'm all the way through. If the drill press table has any tilt error, every 180-degree rotation effectively reverses that.  But one of the holes was still not quite square. The piece did not lie flush against the pantograph link once it was on the shaft. So I drilled another hole, and another, and by the fourth hole, I had one that was sufficiently square. I think the grain of the wood, running diagonally, pulled the drill to the side a little. But one of the holes was still not quite square. The piece did not lie flush against the pantograph link once it was on the shaft. So I drilled another hole, and another, and by the fourth hole, I had one that was sufficiently square. I think the grain of the wood, running diagonally, pulled the drill to the side a little. I have to make sure the axis of the pantograph is exactly square to the back and parallel to the sides. I start by marking a line square to the back edge. I have to make sure the axis of the pantograph is exactly square to the back and parallel to the sides. I start by marking a line square to the back edge.A pencil mark, directly below the hole, on the link, allows me to line it up. I then mark the hole locations by inserting screws in the holes, and tapping them down with a hammer. The point of the screws makes a divot in the wood to mark where to drill the pilot holes.  Getting the location for the front mount. I used two scraps of 18 mm birch plywood as spacers behind and in front of the pantograph to leave sufficient room for the spring cams that will help compensate for the weight of the router later. Getting the location for the front mount. I used two scraps of 18 mm birch plywood as spacers behind and in front of the pantograph to leave sufficient room for the spring cams that will help compensate for the weight of the router later. I lined up the front mount to the pencil line the same way as the back one. Then, inserting screws in the holes, and tapping the screws with a screwdriver and hammer, I mark the pilot hole locations. I lined up the front mount to the pencil line the same way as the back one. Then, inserting screws in the holes, and tapping the screws with a screwdriver and hammer, I mark the pilot hole locations. Mounting the pantograph. Mounting the pantograph. Although the Ryobi router would fit, I used another plunge router with a broken switch. With a broken switch, that router wouldn't be of much use for other jobs anymore. Although the Ryobi router would fit, I used another plunge router with a broken switch. With a broken switch, that router wouldn't be of much use for other jobs anymore.Most people mount routers in jigs by screwing the base to a piece of plywood. This method would work for this mount as well, but I'd lose a little bit of depth of cut. So instead, I'm mounting it by two metal rods. Nearly all router bases have holes for two metal rods, for use with various jigs.  The metal rods need to be mounted to the front of the router mount. I drilled holes in two pieces of wood exactly the right distance for the two rods. The metal rods need to be mounted to the front of the router mount. I drilled holes in two pieces of wood exactly the right distance for the two rods.After that, I slice off part of the blocks, so that I have about 0.5 mm of the hole cut away.  I used a compass to mark the same distance from each hole to make sure I had the center between the two holes, then lined that up with a center line on the front mount. This will ensure that the router's collet will end up on the center line between the two pivot points. I used a compass to mark the same distance from each hole to make sure I had the center between the two holes, then lined that up with a center line on the front mount. This will ensure that the router's collet will end up on the center line between the two pivot points.I put screws in the screw holes, tapped them with a hammer, then used the divots from that to drill pilot holes for the screws in the plywood.  This mounts the router securely to the front part of the mount, but I need support to keep the front from pivoting. So I made some pieces of plywood that reach around the router's handles. With this router, I could have just unscrewed the handles as well. This mounts the router securely to the front part of the mount, but I need support to keep the front from pivoting. So I made some pieces of plywood that reach around the router's handles. With this router, I could have just unscrewed the handles as well. Screwing the pieces together. Screwing the pieces together. Now installing the router mount in the pantograph. Now installing the router mount in the pantograph. It turns out, the pieces of plywood to link the front and back hit the pantograph links, and I couldn't quite tilt it 30 degrees off-square. But I was only a little bit off, so just chamfering the edges of the plywood pieces that hit the links allowed me to get 30 degrees tilt again. It turns out, the pieces of plywood to link the front and back hit the pantograph links, and I couldn't quite tilt it 30 degrees off-square. But I was only a little bit off, so just chamfering the edges of the plywood pieces that hit the links allowed me to get 30 degrees tilt again. I'm still missing the template holder, stock holding table, plunge mechanism, and other bits. But the pantograph is the core of the machine, and I was keen on trying it out. So I used some wooden boxes to hold the template and stock. I'm still missing the template holder, stock holding table, plunge mechanism, and other bits. But the pantograph is the core of the machine, and I was keen on trying it out. So I used some wooden boxes to hold the template and stock.I used a follower and template that I made earlier.  Big tenon milled out. Looking good. Big tenon milled out. Looking good.Next: Making the plunge mechanism (linear glides) Back to the Pantorouter XL |

Wednesday, 17 December 2014

Building the pantorouter XL pantograph

Subscribe to:

Post Comments (Atom)

No comments:

Post a Comment